Master Gear[Standard ・Multi-Master・Custom-made]

Standard Master Gear [Prompt delivery] ※Delivery is made within a week

[Standard]-Master gear is based upon JIS B1751-M00 and AGMA-3A

| Module | P.C.D. | Module | P.C.D. |

|---|---|---|---|

| 0.1 | 30.00mm | 0.15 | 25.50mm |

| 0.2 | 38.00mm | 0.25 | 38.00mm |

| 0.3 | 38.40mm | 0.35 | 38.50mm |

| 0.4 | 38.40mm | 0.45 | 38.25mm |

| 0.5 | 38.00mm | 0.55 | 38.50mm |

| 0.6 | 38.40mm | 0.65 | 38.35mm |

| 0.7 | 38.50mm | 0.75 | 38.25mm |

| 0.8 | 38.40mm | 0.85 | 38.25mm |

| 0.9 | 37.80mm | 0.95 | 38.00mm |

| 1.0 | 38.00mm | 1.25 | 40.00mm |

| 1.5 | 51.00mm |

Multi-Master Gear [Prompt delivery] ※Delivery is made within a week

Made-to-order Master Gear will need over 30days for manufacturing and cost a few thousands US dollars.

Speedy manufacturing of Master gears & quick delivery of Master Gear are always required for inspection.

Standard-Master Gear cannot cover any specifications of Backlash, Addendum modification,

Base tangent length (Tooth thickness), High-tooth, etc

| Gear specification to be measured by Multi-Master Gear | |||||

| Acceptable Backlash, Addendum modification, Base tangent length (Tooth thickness), High-tooth | |||||

| Tooth Thickness (Thinner) |

(1/2 x Pitch) x 88% |

High-tooth | Addendum:: m X 1.25 | Addendum modification |

-0.25 |

| (1/2 x Pitch) x 76% |

Addendum:: m X 1.5 | -0.5 | |||

| Module | P.C.D. | P.C.D. |

|---|---|---|

| 0.4 | 65 | 26.0 |

| 0.5 | 76 | 38.0 |

| 0.6 | 64 | 38.4 |

| 0.7 | 54 | 38.5 |

| 0.8 | 48 | 38.4 |

| 0.9 | 42 | 37.8 |

| 1.0 | 38 | 38.0 |

| 1.25 | 30 | 37.5 |

| 1.5 | 24 | 36.0 |

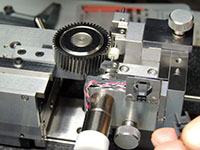

Custom-made Master gear for Double flank gear rolling tester

For excessive gear specification, which cannot be covered with Standard Master gears and ‘Ms+GC’-Master Gears, then,

Custom-made Master gear will be necessary for measuring special gears

Please contact us with gear data with drawing, you will get suitable Master gears for your inspections